Sub-contract fabrication work:

■ Offshore special fabrications

■ Tundishes for steel production

■ Autoclaves and Rotary Dryers

■ Cyclones and Multi-cyclone arrays

■ Ducting

■ Silos

■ Tanks

■ Bridge Work

■ Gantries/Structures

■ Access steelwork

Offshore Special Fabrications

Over the past 20 years CF Struthers has provided numerous offshore fabrications. All fabrication, NDE, painting, trial assembly, inspection, packing and shipping completed in-house to the exacting standards for the supply of equipment for off-shore applications. Some examples are shown below:

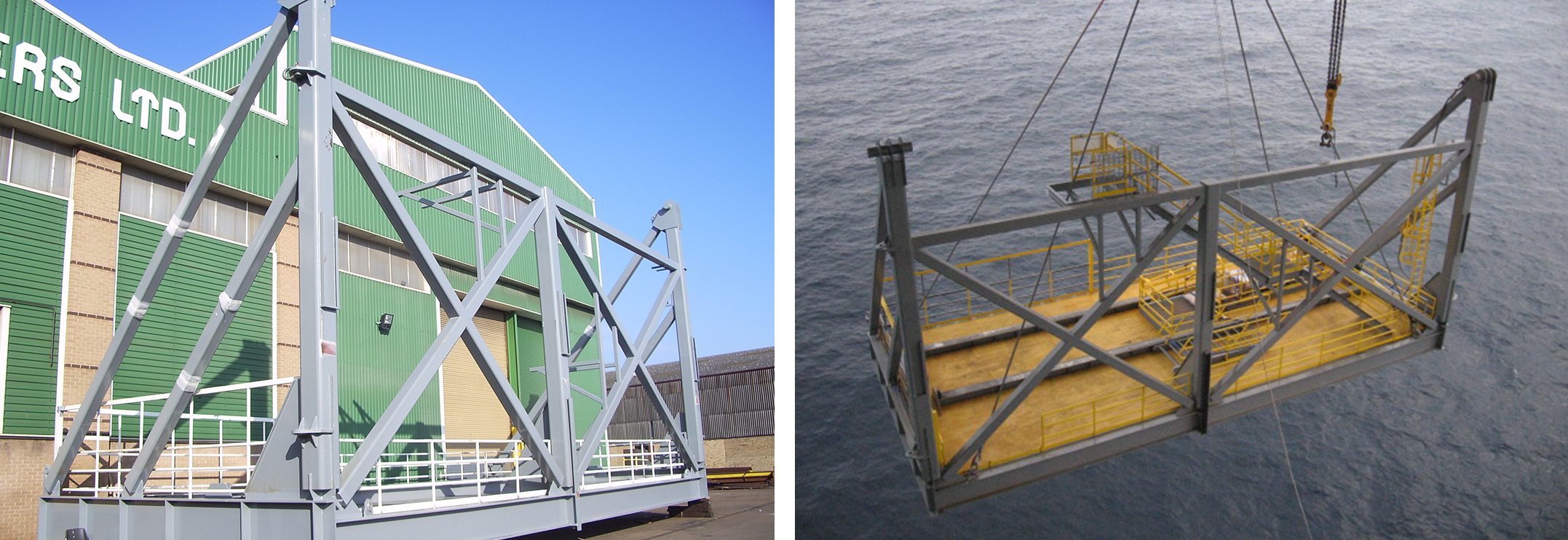

Images Above: Fabrication and supply of two 350 tonne SWL lifting frames for ODS International

Images Above: A BD Flowline Protection Frame supplied for Centrica

Images Above: A tree handling platform for a North Sea offshore drilling platform

Images Above: A Pollution Control Unit shown fully assembled ready for inspection at our Works and then installed below the Ensco Monrovia Drilling Platform

Images Above: A BOP transporter system supplied for the Pride North America platform. A PSA manipulator arm for offshore applications

Tundishes for steel production

CF Struthers offer services to refurbish client equipment. Typical contract for British Steel includes detailed non destructive test followed by report of necessary repairs to client. The below image shows a tundish used in the steel making process which has been refurbished by CF Struthers.

Autoclaves and Rotary Dryers

■ Fabrication to customer specification.

■ Autoclaves static and rotary.

■ Rotary dryers, carbon steel and stainless steel.

■ On site repair service available

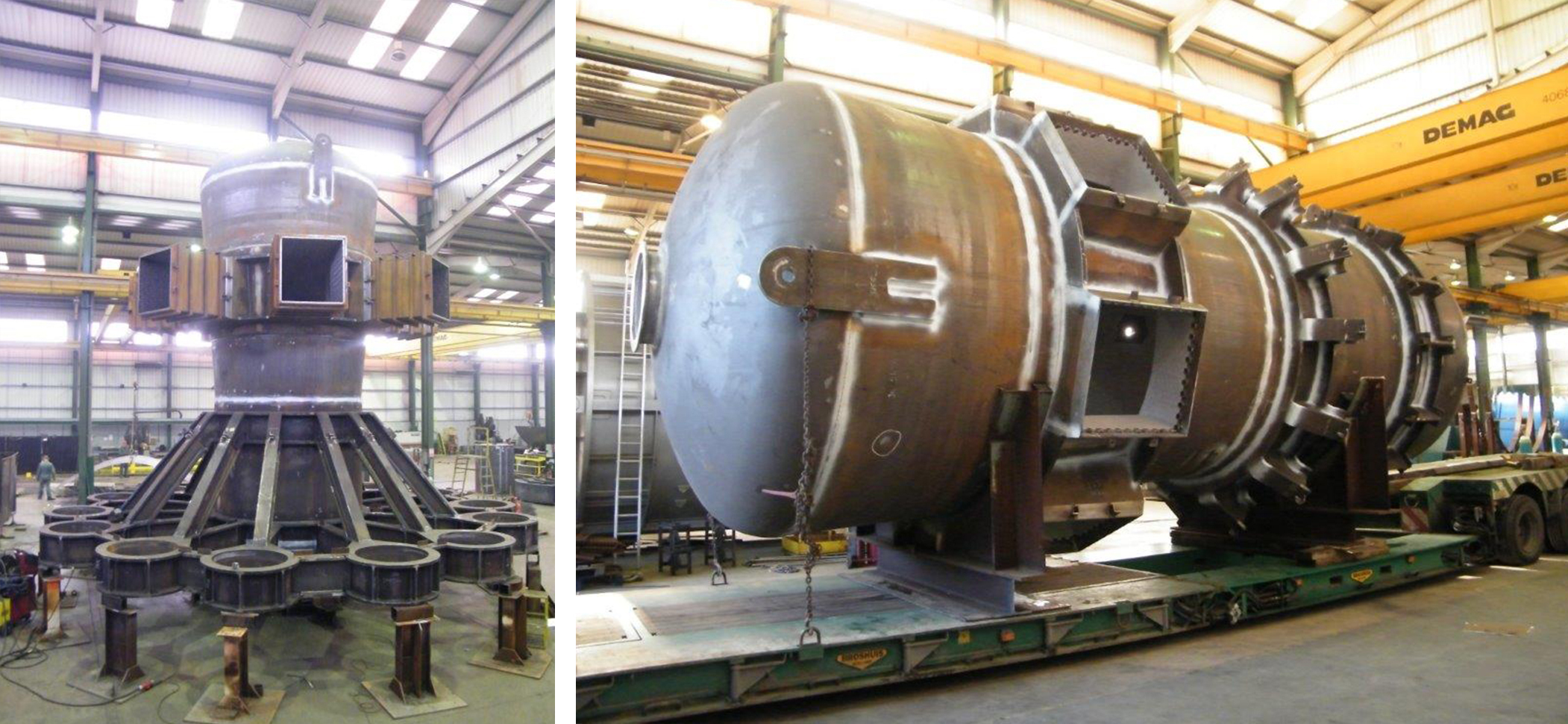

Cyclones and Multi-cyclone arrays

Complete supply fabrication of heavy walled 25 – 70mm Reactor Cyclone Riser and Support System. Full trial assembly in our ‘High Bay’. This unit was manufactured to BS 5500 pressure vessel code to customer design and specification. (Van Tongeren)