CF Struthers first developed the finned tube helical coiling technology in 2001, we have continued to improve and perfect the manufacturing process, which has enabled the circular waste heat recovery unit to be marketed worldwide. The coils are constructed from ‘finned’ extended surface tubing and can be formed in excess of 6m in diameter as required by design. All welds are subject to 100% radiography and coils are hydro tested prior to assembly into the casings.

Importantly, the entire CWHRU package is manufactured in house at our Hull based, UK Works including casings, full lining systems, integral multi-louvre bypass damper (patented), stacks and silencers.

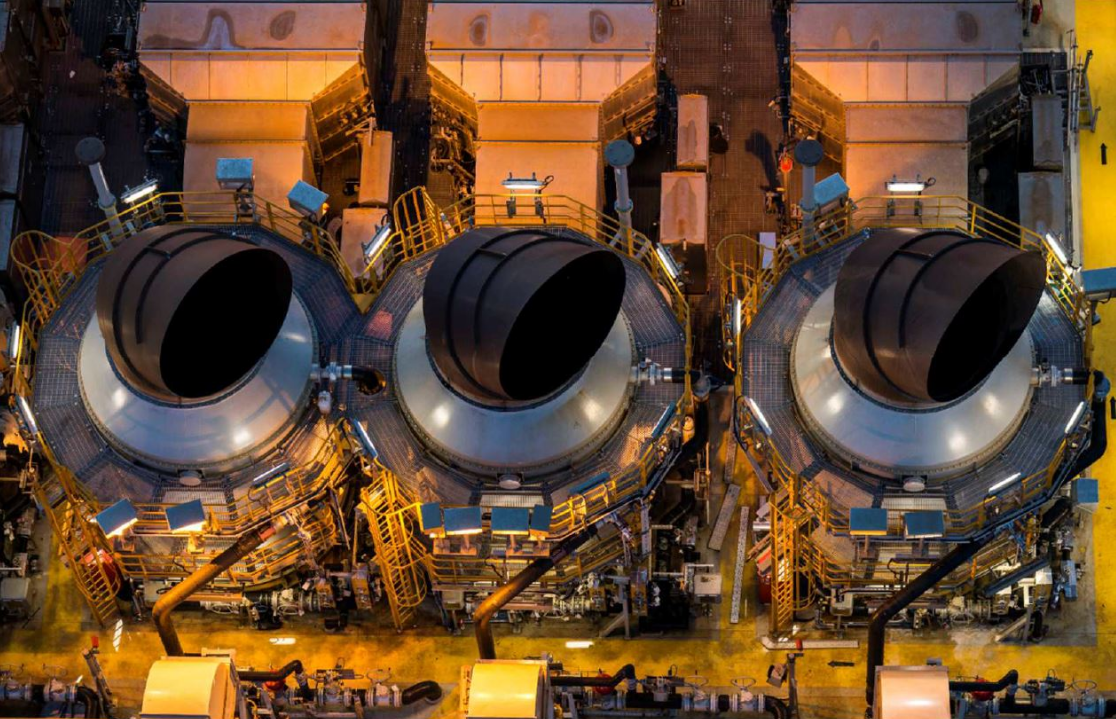

Images Above: Three CWHRUs manufactured for the Delta House LLOG Platform, recovering heat from Three Solar Taurus T60 Gas Turbines

Image Above: Three of four CWHRUs supplied for the Jordbaer Teekay FPSO, Solar Titan T130 Gas Turbines

CF Struthers manufacture and test the whole CWHRU, including coils, casings, integral bypass, integral bypass damper and carry out a Factory Acceptance Test (FAT) prior to packing and shipping.

The amount of heat recovered by the CWHRU is controlled via the damper, the patented integral radial vane damper was invented by CF Struthers. It controls the flow of GT exhaust gas to a) the Coil Annulus, b) Bypass or c) Modulating as required, allowing some exhaust gas to spill up the bypass in order to match the thermal demand from the downstream plant.

The design of the damper is inherently safe by ensuring that at all times there is a route to atmosphere for the GT exhaust gas (failsafe).

This unique damper system is manufactured in stainless steel (typically 304 or 316) plus Incoloy sealing systems. High tolerance fabrication and machined parts are used to ensure high sealing efficiency and extremely low maintenance

The damper is normally hydraulically actuated (pneumatic actuation can be provided). Operation is controlled via a Hydraulic Power Unit (HPU) which is provided as part of the CWHRU package. The low maintenance damper system has few moving parts and nominally provides in excess of 99% sealing, this can be increased to 100% sealing for special applications if required.

We offer our WHRUs as a complete turnkey package including the HPU. The CWHRUs are shipped fully assembled to minimise site installation time and cost.

Images Above: Typical load out of CWHRU at CF Struthers Yard and Shipping of CWHRU – Hull dock less than ½ mile

CF Struthers have manufactured/supplied in excess of 100 Waste Heat Recovery Units of which 80 being of the circular design and 20 being the ‘traditional’ serpentine type with integral bypass and damper arrangement.

■ Patented Circular Design (Struthers Energy & Power)

■ Patented Helical Coiling Manufacturing Process (Struthers Energy & Power)

■ Units are delivered either to site or ex works. One piece module (except stack)

■ CF Struthers fabricate the casings, which are usually carbon steel. We manufacture and install the internal lining system to provide 60°C external skin temperature (cold casing).

■ Dampers are manufactured and tested in house.

For a complete list of our CWHRU projects please contact us.